Recommended for You

Discover new deals on top-of-the-line printing solutions.

Browsing History

- Choosing a selection results in a full page refresh.

Graphtec FCX4000 Series achieves high quality cutting with improving of the quality and accuracy by enhancing rigidity of the sliding mechanism and the driving system. It is the best flatbed type cutting plotter that has a high usability and productivity equipped with new functions.

Graphtec FCX4000 is an affordable cutting solution for small to medium print on demand jobs - using electrostatic to hold media. The 60ES model cleanly fits four A3 + sheets for high productivity. Operation is intuitive with its new control panel, 3.7” LCD screen, and USB / Barcode functionality. Max. Speed 29.5"/sec, Max. Force 600 gf.

FCX4000 Series are the ideal cutting plotter for high-precision and medium-heavy material crafting jobs and is suitable for cutting intricate designs on vinyl, photo-masking films, foam material, cardboard, oil board, and sandblast resist rubber.

Suitable for PET, Polyamide, Cardboard, Microflute board or Industrial materials with precise adjustable cut pressure up to 600 gf. Flatbed FCX4000 Series is the most economical solution for cutting thick, hard materials that cannot be fed through a roll-feed/friction-feed cutting plotter.

Graphtec FCX4000 Series come standard with a dual head configuration allowing pens, cutting tools, and creasing tools to be loaded simultaneously.

A new reverse creasing function allows alignment and creasing on the reverse side of the printed card stock to prevent traces of the creasing operation from appearing on the printed surface.

A simple function to create fold lines for clean folding on micro-flute and cardboard has been enabled. Up to three fold lines can be selected. If two or three fold lines have been selected, the spacing between the lines can also be specified. Repeated creasing operations can also be specified for each of the lines.

Cutting and creasing can be carried out from reverse-side when using the registration marks. This prevents crease line from appearing on the printed surface.

FCX4000 Series are perfect for designers and prototyping in the offset printing, digital printing, packaging industry, fashion industry, as well as road sign making, stone & glass sandblasting/etching, the electronic film industry, and architectural model building.

The FCX4000 Table employs 110 Volt Electro-Static Hold-Down Technology suitable for securing light-weight material which assures precise cuts without slipping. This feature holds media in place utilizing an electrostatic charge that is generated by electrodes arranged inside the panel.

The FCX4000 series has 2 tool holder in the carriage.

Using 2 different tools in the same job increases work efficiency.

Settings can be easily set using the large

3.7-inch LCD (240 x 128 dots).

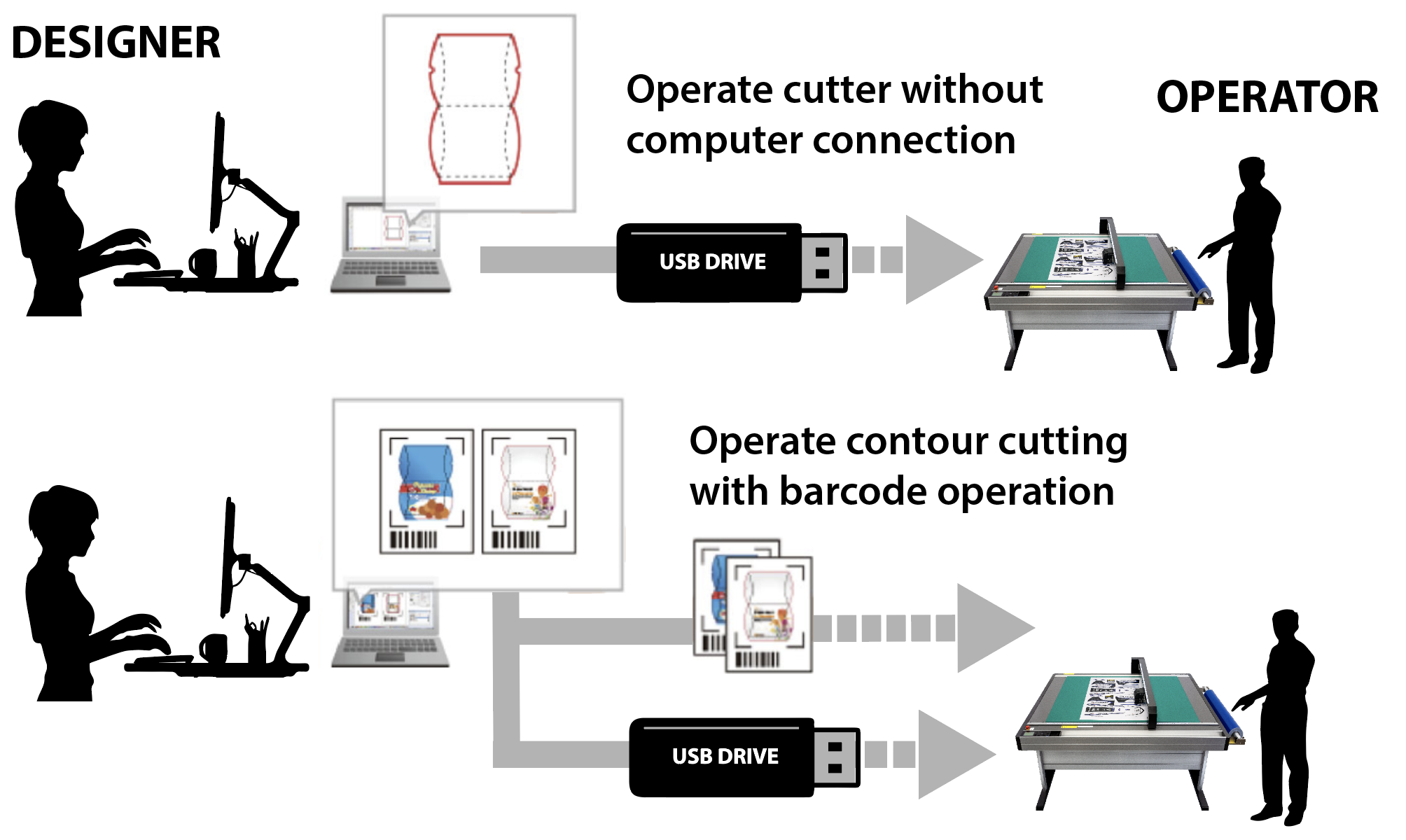

Cut and plot data is created with Cutting Master 5 or Graphtec Studio 2 software. The saved data may be transferred to a USB Thumb Drive and the cut plot data file can be selected from the USB on the FCX4000 using its menu operations. This simplified work-flow enables users to operate without being connected to the computer.

Data Management using Bar-code Function with USB flash memory

When performing contour cutting, also known as “Print & Cut”, the cutting data is automatically selected from the prepared USB flash memory. The FCX4000 scans the bar code printed on the media then automatically performs the contour cutting job. This emerging method helps to prevent operator error of using incorrect data - thus improving workflow efficiency.

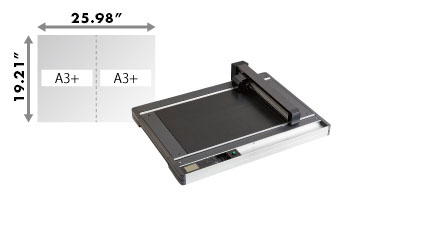

FCX4000-50 ES |

FCX4000-60 ES

|

|

Table Size: 42.87" x 35.31" x 8.03" • Effective Cutting Area: 25.98" x 19.21" |

Table Size: 55.31" x 42.08" x 8.03" (w/o stand) • Effective Cutting Area: 38.4" x 25.9" |

|

|

| MODEL | FCX4000-50ES | FCX4000-60ES (stand optional) | |

|---|---|---|---|

| Configuration | Digital servo system, Flatbed | ||

| Media hold-down method | Electrostatic panel | ||

| Effective cutting area | W 25.98" x H 19.21" | W 38.4" x H 25.9" | |

| Mountable media (Y-axis direction) |

21.10" | 27.97" | |

| Maximum cutting speed | 29.5"/s (1 to 75 cm/s in 23 steps) | ||

| Cutting pressure | Tool 1: Max. 5.88 N (600 gf) Tool 2: Max. 5.88 N (600 gf) |

||

| Cutting force settings | Tool 1: in 48 steps, Tool 2: in 48 steps | ||

| Minimum character size | Approx. 10 mm square (varies with character font and media) | ||

| Mechanical resolution | 0.005 mm (5µm) | ||

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ (*1) : 0.025 mm |

||

| Distance accuracy | Max.0.2% of the distance moved or 0.1mm, whichever is larger (excluding contraction of media, in plotting/cutting mode) (*2) |

||

| Perpendicularity | Max 0.3 mm / 16.93" (excluding contraction of media, in plotting/cutting mode) |

Max 0.4 mm / 24.01" (excluding contraction of media, in plotting/cutting mode) |

|

| Repeatability | Max 0.1mm (excluding contraction of media, in plotting/cutting mode)(*2) | ||

| Standard interfaces | USB2.0 (Full Speed) / RS-232C / Ethernet (10BASE-T/100BASE-TX) | ||

| Buffer memory | 2MB | ||

| Command sets | GP-GL / HP-GL™ / AUTO (Automatic switching in GP-GL and HP-GL™) | ||

| Number of tools | 2 tools | ||

| Cutter blade, pen, and tool types | Cutter blade: supersteel Pen: water-based fiber-tip pen Creasing/scoring tool |

||

| Operating panel | 3.7-inch graphical LCD (same LCD as the FCX2000) | ||

| New features | Dual configuration, Creasing in the curve, Perforation cutting (performed by the force control), Data management using the bar-code, Offline cutting operation using the USB memory, Display the degree of wear for the cutting blade, Confirming the cutting object size, Draft mode (higher throughput in arc) | ||

| Power supply | 100 to 240 V AC, 50/60 Hz (Auto switching) | ||

| Power consumption | Max. 120 VA | ||

| Operating environment | Temperature: 10 to 35 degree C , Humidity: 35 to 75% RH (non-condensing) |

||

| Guaranteed accuracy environment | Temperature: 16 to 32 degree C, Humidity: 35% to 70% RH (non-condensing) |

||

| External dimensions (*3) (W x D x H) |

W 42.87" x D 35.31" x H 8.03" | W 55.31" x D 42.08" x H 8.03" (including stand : W 55.31" x D 43.18" x H 35.27") |

|

| Weight | approx. 63.93 lbs (29kg) | approx. 83.77 lbs (38 kg) (including stand 121.25 lbs (55 kg) |

|

| Compatible OS 6(*4)(*5) | Windows 11 /10 / 8.1 / 64-bit editions & MacOS 10.2 (Sierra) to 10.13 (Ventura) |

||

| Included Software (*6) | Graphtec Studio 2, Cutting Master 5 Plug-in for Windows and Mac | ||

| Compatible Standards |

Safety | UL/cUL, CE mark | |

| EMC | VCCI Class A, FCC Class A, CE mark (EN55032, others) | ||

Phone No:

905-326-2790

E-mail Address:

info@precisiontoner.ca

Don't miss out on sales and special promotions - sign up for our email newsletter today and receive deals!

© 2026, Precision Toner